Features & Specifications

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

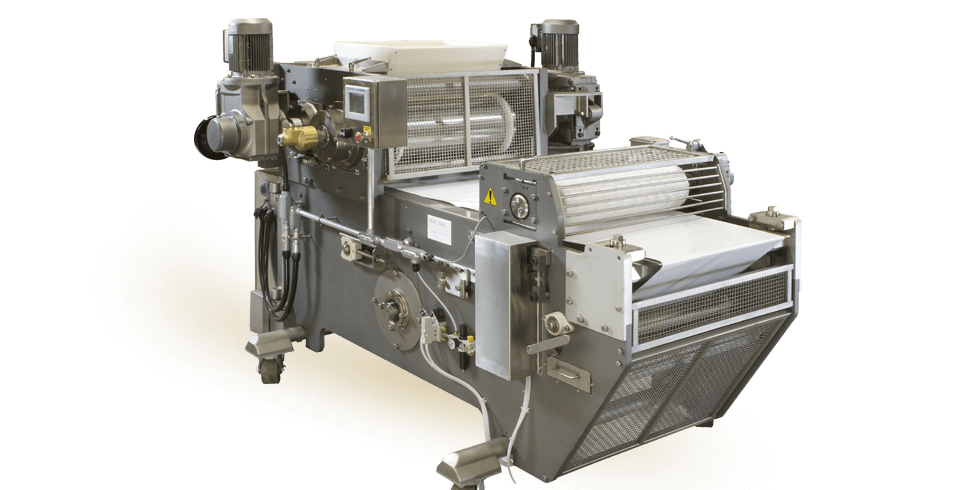

- Single or double cutting roll arrangements can be provided depending on the complexity of the shape desired or if multiple shapes will be run in quick succession.

- All die rolls are designed for easy removal and installation so product changeovers can be accomplished quickly and efficiently.

- Safety-interlocked, stainless steel guards prevent unsafe operation or access to the machine while in operation.

- Mushroom head electrical E-stops are provided for emergency shutdown.

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- All guarding is interlocked with the control safety circuit or mechanically fastened to prevent operator access

- No painted materials in the product zone

- Guards designed for ease of inspection during production