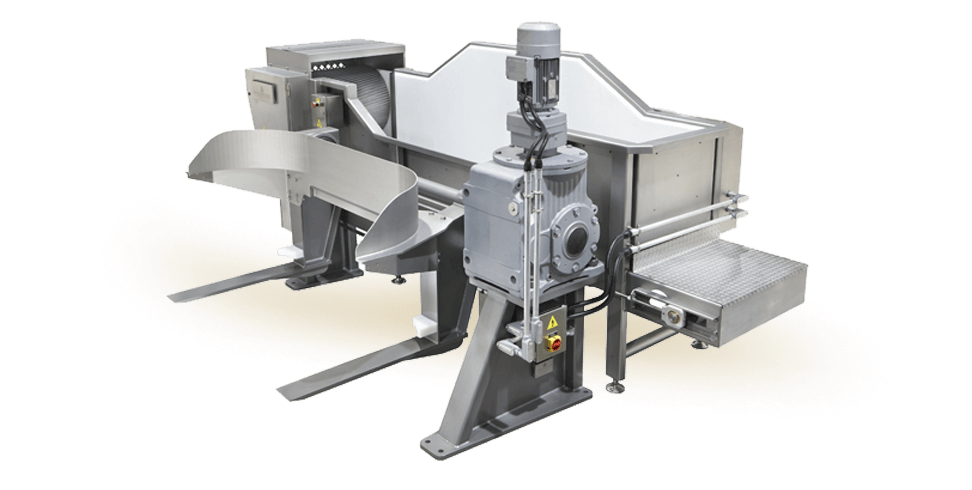

Features & Specifications

Additional Equipment Photos

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

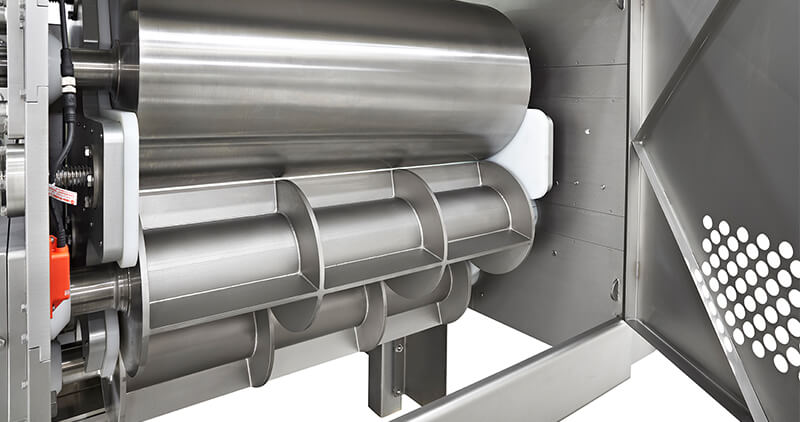

- Multiple Dough Processing Options: Chunker Rolls, Kibbler Knives or Sheeter Rolls

- Laytime conveyor size is customized to production capacity (dough batch size and proofing time required)

- An optional dough dump station can be integrated

- Dough batches can be dumped from industry standard or plant specific troughs.

Contact us for a full list of features and specifications.

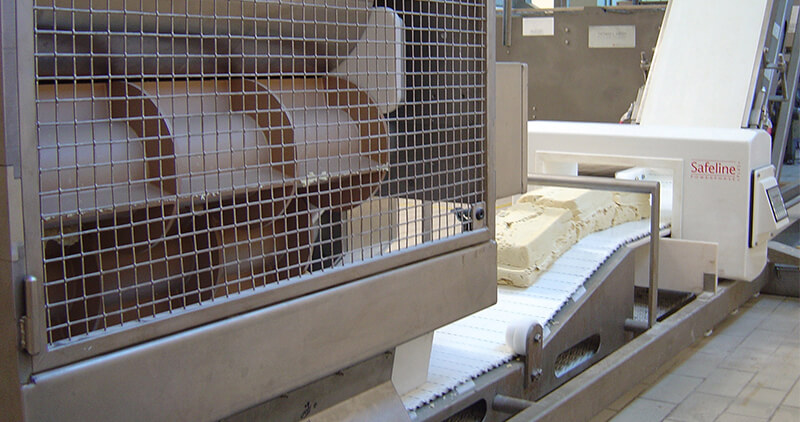

Request More InfoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Guards are designed to meet latest safety guidelines; electronically interlocked where appropriate

- Side wall materials designed for easy dough release and ease of cleaning

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- All component controls are designed for automatic processing

- Optional sensors around the machine monitor dough flow in and out of the processing attachments