Features & Specifications

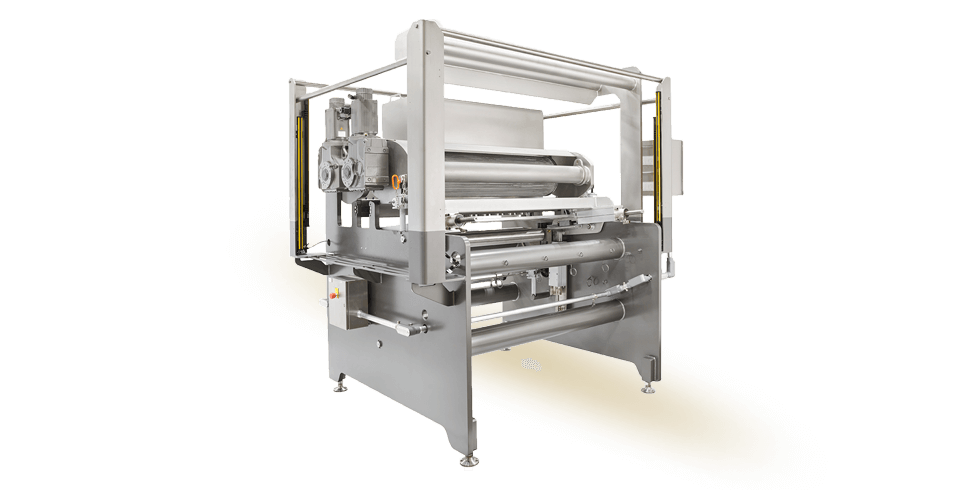

Additional Equipment Photos

See it in Action

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Product settings can be stored as a machine “recipe”

- Servos control wire positioning, stroke length, and enable infinite cam profiles – stroke, wire height, drop and band-raise and can be changed quickly between production runs for different products

- The hopper, roll assemblies, harp and wire frame are designed to be easily removed for sanitation and preventative maintenance procedures

- Operators can safely access all parts of the machine during changeovers and plant scheduled maintenance

- The Servo-Driven Wirecut Machine is also capable of frozen dough applications.

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Light curtains stop the machine immediately when the curtain is broken

- Light guard system maximizes access to machine components for maintenance or wash down

- The hopper, roll assemblies, harp and wire frame are designed to be easily removed for sanitation and preventative maintenance procedures.

- Operators can safely access all parts of the machine during changeovers and plant scheduled maintenance.

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

- Touchscreen controls for wire positioning, stroke length and infinite cam profiles to ensure production is safe and easy to control

- Controls can be tied into an existing dough feeding system or applied to a turn-key, automated, dough handling system

- A touchscreen control interface is mounted on the side of the machine to adjust roll and cutting speeds