Features & Specifications

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Flexible heat transfer modes and control

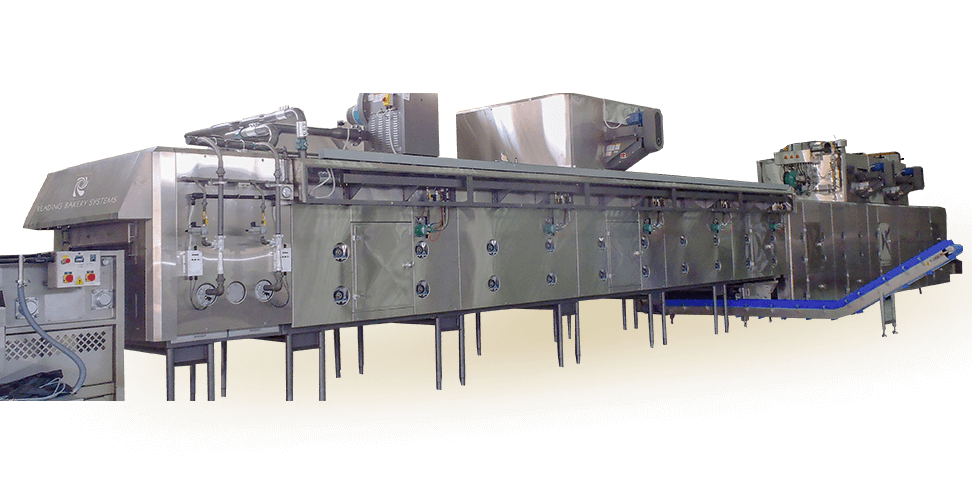

- Factory built sections for quick and easy installation

- Modular design for optimal baking profile control

- Oven over kiln option for two pass, space saving production efficiency

- Air circulation and exhaust systems are completely controllable

- Feedback based control system enables automatic monitoring and adjusting of the oven

RBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key safeshield features of this machine include:

- Fully automated operation

- Low pressure gas system designed to Factory Mutual and IRI codes

- Active flame and temperature monitoring

- Explosion prevention panels and doors built into the system

- Automatic fire suppression systems

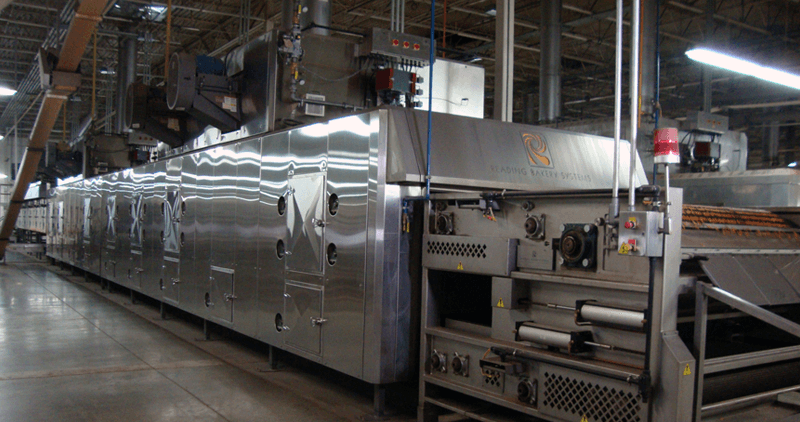

- Easily accessible baking chamber through large access doors

- Flat floor in baking chamber allows easy removal of accumulated product debris

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production running safely and efficiently.

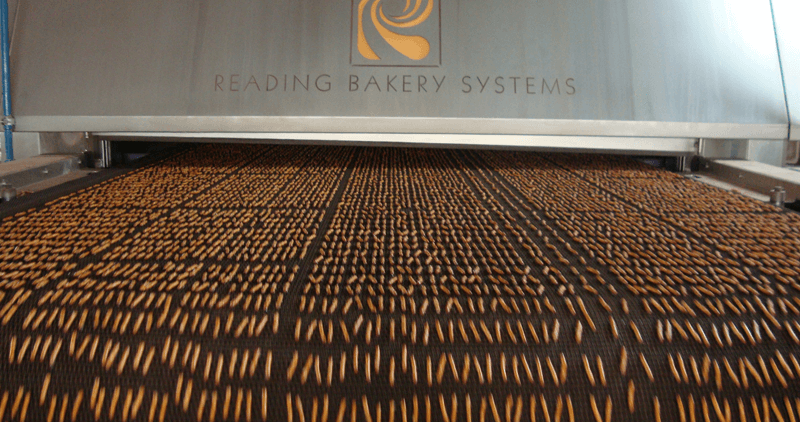

- Automatic operation and recipe based control system

- Temperatures regulated via feedback loops

- Monitoring of parameter trends throughout the oven allows operators real time understanding of the baking process